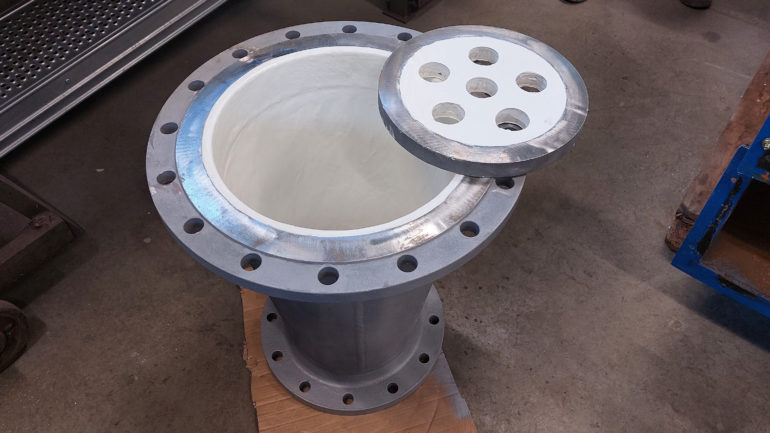

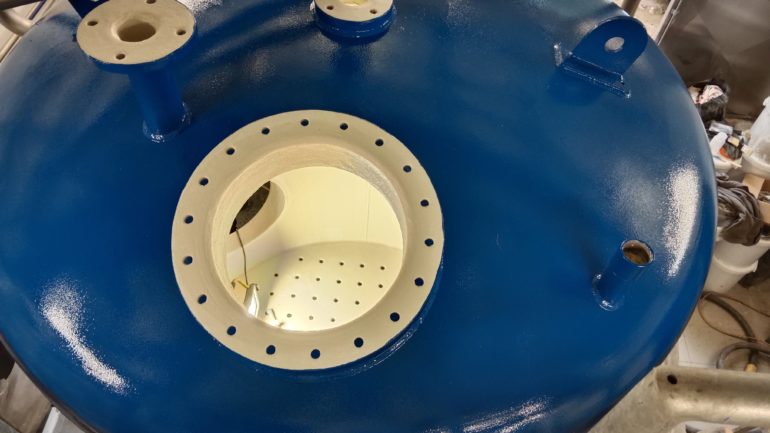

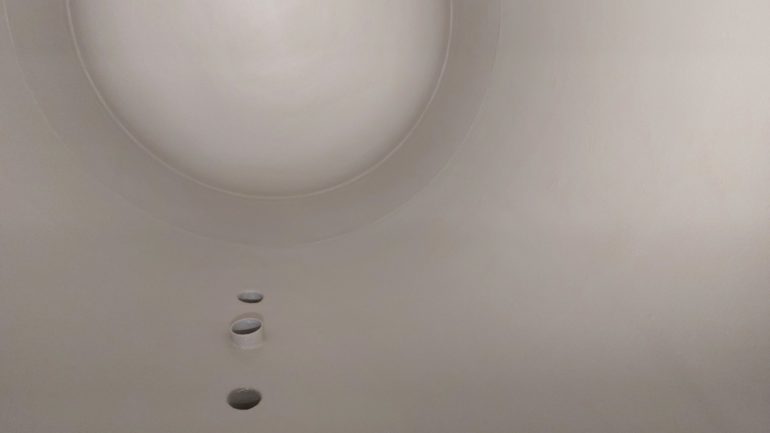

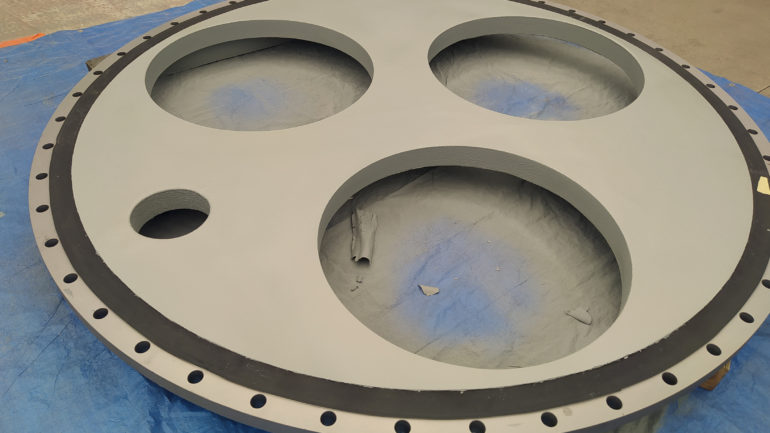

Application of special surface treatments for the most demanding conditions

Special surface treatments

Technology for surface treatment

Our company develops blasting box technologies of first-class quality. We size them based on the requirements and needs of our customers. We also design them as a complex unit, including compressor stations and compressed air distribution.

We design high-capacity paint shops and paint booths with low acquisition costs, minimal structural intervention into the building and acceptable operating costs. We carry out their construction on a turnkey basis, including construction work and equipment with the latest application technology according to the needs and wishes of the customer. We provide service and maintenance of paint boxes from our centres in Most, Brno and Ostrava. Our development and testing centre is located in Most – Komořany.

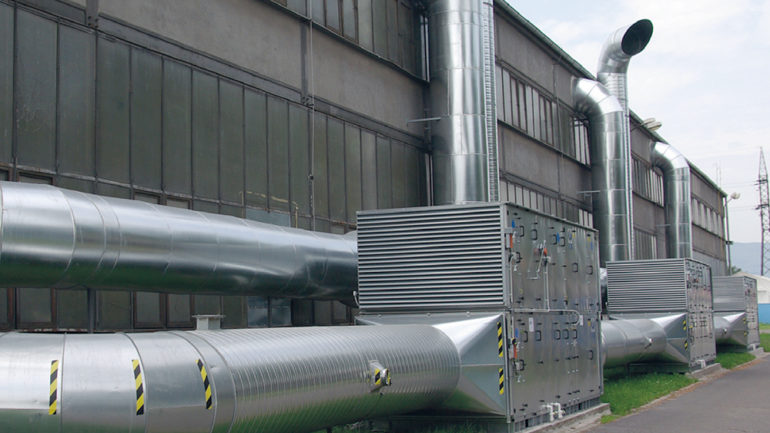

Our company develops and supplies complete compressor station technologies including compressed air distribution equipment. We size them based on the requirements and needs of each customer and the possibilities of their production facilities. Deliveries are turnkey, including related construction work. We provide service from our centres in Most, Brno and Ostrava. Our development and testing centre is located in Most – Komořany.

CORROTECH ENGINEERING s.r.o. develops and supplies technologies for mobile metal abrasive recycling and air filtration equipment. We dimension and implement technology deliveries on a turnkey basis, including the supply of other necessary equipment. We service these devices from our centres in Most, Brno and Ostrava. Our development and testing centre is located in Most – Komořany.

About the company

As the exclusive distributor of CORROCOAT and REZORECT technology in the region, CORROTECH ENGINEERING s.r.o. has a highly qualified team of experts for industrial coating applications and unique application methods based on the latest technologies, which it also develops and supplies. Our own technological background with centres in Most, Brno and Ostrava together with the professional potential of our staff enables us to solve our clients’ requirements promptly, qualitatively and first time.

We offer:

- more than 20 years of experience in the fight against corrosion

- effective protection under the most demanding operating loads

- effective protection for new and damaged equipment

- long-lasting and effective protection compared to conventional solutions

- unique application methods using the latest technologies

- turnkey design and manufacture of blasting box technologies

- design and production of turnkey paint shop technologies

- design and manufacture of compressor stations and recycling plants

- design and manufacture of all filtration equipment

- corrosion assessment of new components

- development of customized designs as a prevention against corrosion damage

- anti-corrosion solutions that are safe and environmentally friendly

- application procedures that solve the problem long-term and first time

- solutions that are cost-effective in the long run